Negocio

Tiempo de liberación:2019-03-29

Tiempo de liberación:2019-03-29

I. Rockwool equipment

1. Automatic charging system

The automatic batching and charging system consists of weighing hopper, vibrating feeder, belt conveyor, PLC

control system etc.

Feeding material

|

Item |

Name |

Standard code |

Technical requirement |

|

01 |

basalt |

Q/0323SLYYM001-2012 |

Enterprise standard |

|

02 |

dolomite |

Q/0323SLYYM002-2012 |

Enterprise standard |

|

03 |

coke |

Q/0323SLYYM003-2012 |

Enterprise standard |

|

04 |

slag |

Q/0323SLYYM004-2012 |

Enterprise standard |

2. Rockwool cupola furnace

|

Cupola blasting air |

400~500℃ |

|

Blast volume |

Normal 4000~5000 Nm3/h |

|

Max. 6500 Nm3/h |

|

|

Circulating water |

100 m3/h |

|

Oxygen enrichment |

600~110 Nm3/h |

|

Molten temperature |

1400℃~1450℃ |

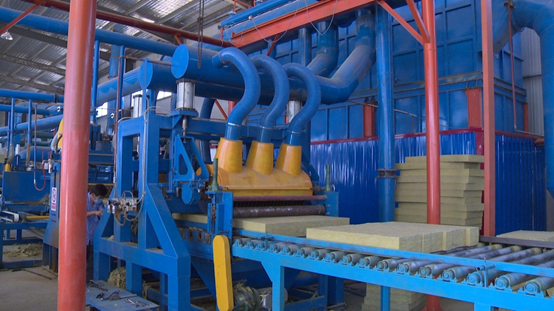

3. Spinning machine

The spinning machine is central part for fiber forming.

|

Rollers |

RPM |

Cooling water flow |

|

1# |

2800~3500 |

1000 L/h |

|

2# |

4000~5000 |

1200 L/h |

|

3# |

5000~6000 |

1500 L/h |

|

4# |

5500~6500 |

1500 L/h |

4. Wool collector

Technical parameters

|

Mats width |

2400 mm |

|

Max. linear speed |

100 m/min |

|

Drum diameter |

Φ 5000 mm |

5. Curing oven

Temperatures in different sections

|

Zone |

1 |

2 |

3 |

4 |

|

Temperature |

200~220℃. |

230~240℃. |

270~290℃. |

270~290℃ |

6. Pendulum

7. Pleating machine

Technical parameters

|

Pleating thickness |

30~250 mm |

|

Speed |

2.4~12 m/min |

|

Vertical distance between rollers |

10~610 mm |

|

Power |

28.4Kw |

8. Cutting system

9. Dust collector

II. Slagwool equipment

Electrical slag regulating and holding furnace

III. Foundry equipment

1. Teapot ladles

2. Cupola furnace